Electrical control panels are a collection of devices that use electrical power to control industrial equipment. These panels are used to maintain orderly control over industrial equipment to achieve multiple mechanical goals. The closed metal box has two main parts: the panel structures and electrical components. We will examine the industrial control panel and its benefits.

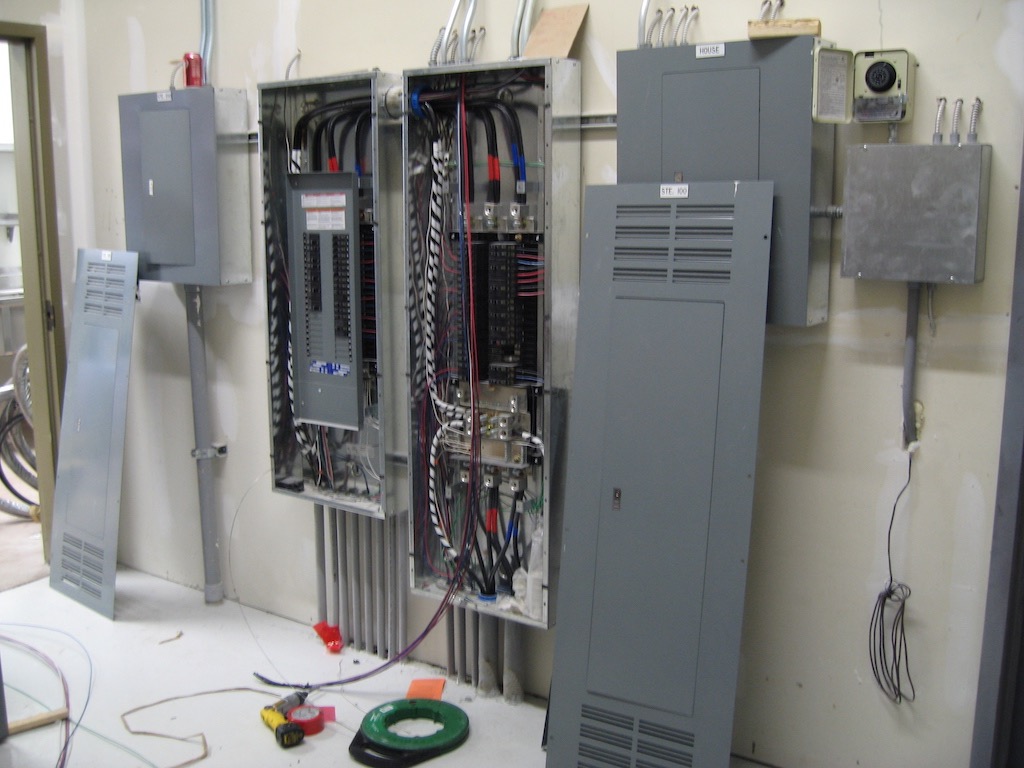

Inside a Electrical Control Panel

Panel structure: A panel structure is a metal enclosure with a backpanel that looks like a breakers box. The enclosure can have one or two metal doors depending on the size. It is made from steel or aluminum. These boxes pass stringent quality checks. UL safety ratings ensure the boxes are explosion-proof and contamination-proof. They’re also waterproof and safe to use indoors and outdoors. It also comes with a panel that is mounted on the back of metal box to support the wire ducts.

Electrical Components: Depending on the function of an industrial control panel there can be multiple electrical elements.

Electrical control panels typically have:

- The main circuit breaker is in the control panel. This circuit breaker has a switch on the outside to turn off power when necessary.

- Transformer that switches down the power to provide enough supply for smaller devices.

- Terminal block to join two power lines.

The electrical control panel can be equipped with programmable logic controls (PLCs), network switches, contactors, and other components.

Electrical Control Panel Benefits

- They are vital for industrial automation, as they continuously monitor the different industrial controls. They help professionals control and organize production goals.

- Panels can be custom-made for industries. For a more cohesive control over mechanical aspects of machinery and industrial equipment, they can choose a simple industrial control panel or a complex industrial relay system.

- The experts are able to provide data at any time and can monitor the equipment.

- These panels can handle complex electrical controls. These panels can handle the most complex industrial setup if you hire a team of experts to design them according to the required requirements.

- The panels are weatherproof and can be used both indoors or outdoors. They won’t rust, deteriorate, or become damaged by changing weather conditions.

- Electrical control panels have been designed to be hazard-proof. This means that there is no danger of electric shocks or fires.

- Many companies today offer “aesthetically pleasing” control panels for industrial applications. These panels are not a distraction to the beauty of a building.

- Electrical control panels make the job of industrial experts easier. Experts can control different machines or operations using the controls on a panel.

- Increasing efficiency can reduce the cost of processing for industries.

- Experts can control mechanical processes so there is very little chance that a flaw will cause an undesirable outcome.

Electrical control panels play a vital role in many industries including oil and gas, food and beverage manufacturing, agriculture and more. Contact a leading industrial control panel manufacturer to get the technology you need.